Products

Why we?

Company

culture

European standards, made in China

Company

development

The company was founded.

The LDLASER brand has become well-known in the industry. Gradually, the company began to develop in the foreign market.

Entering the high-capacity market. Establishing cooperative relations with many major national scientific and technological institutions, such as the State Grid Corporation of China and the Second Artillery Corps of Beijing.

The company has expanded to 200+ points of sale across the country. The European R&D center was founded and put into operation. An R&D center in Jiangsu was also established.

The Shandong Research Center was founded.

A new 50 kW product was launched and a 50,000-meter production base was put into operation in the Shanghai District of Jinan.

A product was launched – a world debut with a capacity of 120,000 W. Received the Excellent Exploration Award at the China Industrial Exhibition.

Opening of an official representative office in Ukraine (Dnipro). This is an important step in strengthening the brand’s position in the Ukrainian market and improving the quality of customer service.

Company in

numbers

LD Laser was founded in 2012 and is a reliable supplier of high-tech equipment and solutions specializing in CNC laser cutting machines.

Service users

Countries of sale

Technical staff

Total company area

Projects

implemented

Events and news

Laser Cutting of Metal

In modern industry, the precision of metal processing and the quality of finished products are key to ensuring competitiveness and increasing sales. One of the most effective technologies in the production process has become laser cutting of metal, which shortens manufacturing times, reduces material waste, ensures smooth edges, and minimizes product deformation. The use of high-tech equipment allows for high speed and clean cuts, which is important for both mass production and custom orders.

A modern and reliable metal laser cutting machine is an essential tool in production, as it allows for the manufacturing of high-precision, high-quality parts without complex mechanical operations.

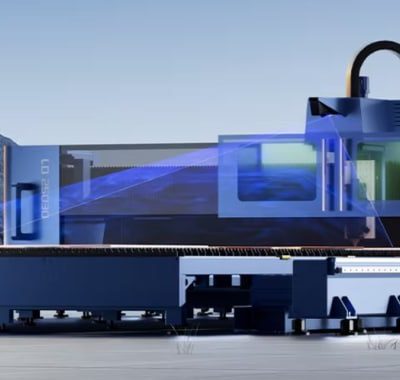

Metal Laser Cutting Machines

A laser machine for cutting metals is a high-precision, modern piece of equipment designed to cut metal sheets, pipes, various profiles, and other workpieces using a focused laser beam.

These machines are equipped with a CNC system, which allows for process automation. Thanks to their use, it’s possible to achieve high accuracy in the production of items of any shape, regardless of complexity.

Non-contact cutting eliminates material deformation and ensures a clean, smooth cut, with the metal surface requiring no further processing. This shortens the production process, so orders can be completed faster and with higher quality.

There are different types of laser cutting machines. They all have their own features, are used for different materials, and are suitable for specific tasks.

Advantages and Disadvantages of CNC Laser Cutting Machines

CNC machines are automated equipment for performing precise operations. If you need to solve complex production tasks, manufacture parts of non-standard shapes, and ensure high cutting accuracy, a CNC metal machine is the best option. Laser cutting, thanks to its high speed and precision, increases productivity.

Advantages of CNC machines:

- High-quality cut—requires no additional processing.

- Eliminates mechanical damage to the material surface.

- Ability to accurately process complex contours.

- Process automation.

- Universal application—suitable for different materials.

- Non-contact processing.

- Economical use of materials—due to reduced cutting waste.

- No metal chips or shavings.

- Safe operation and minimization of accident risk.

- Long service life.

CNC laser machines provide consistent results in mass production. This means that each item will be an exact copy of the others. This technology is more effective than traditional cutting methods, especially when complex cuts are needed.

However, a CNC laser cutting machine also has disadvantages:

- Limitations on material dimensions and thickness.

- Efficiency is dependent on the software.

- High electricity consumption.

- Requires equipment maintenance.

- High cost.

Additionally, laser cutting can cause thermal distortion of thin metal sheets or part edges due to the heat generated. Production speed also depends on the type and thickness of the material.

CNC laser cutting machines are a high-tech solution that increases production efficiency and product quality. By using them, you can achieve maximum cutting precision, minimize human error, and speed up the manufacturing of parts of varying complexity.

Operating Principle of a Laser Machine

A laser beam is used for the precise cutting of pipes, profiles, and metal sheets. This is a non-contact process that eliminates material deformation. The cut is clean and smooth, requiring no additional processing. And thanks to Computer Numerical Control (CNC), the laser metal cutting machine ensures high-precision work and production speed.

A powerful laser beam, generated from electrical energy, is used to process various metals. It passes through a special lens system, is directed onto the material as a tiny dot, and heats it to the melting/vaporization temperature. The laser beam then melts the material along the contour of the desired shape, and a special gas removes the molten metal with virtually no residue.

Laser cutting of metal with a CNC machine is performed in several stages:

- Programming: Software creates G-code, which tells the machine the exact movement path.

- Material preparation: Metal sheets or pipes are placed on a special table. If necessary, the item is cleaned and secured.

- Laser focusing: The laser beam is directed at the material, burning and quickly heating the metal to the required temperature so it melts.

- Laser cutting: The CNC controls the laser’s movement along the specified path, allowing for cutting of complex shapes.

- Gas supply: A specific gas, such as nitrogen or oxygen, is supplied to the cutting area to remove the molten material.

Thanks to this operating principle, laser cutting of metal produces precise cuts with smooth edges and minimal waste.

Design of CNC Laser Machines

CNC machines used for laser cutting of metal combine mechanical precision, modern technology, and functionality. This is all thanks to their special design and operating principle.

What are the main components of a metal laser cutting machine?

- CNC System: This is the software module that controls the laser’s movement, the power of the light beam, and the gas supply.

- Laser Source: Generates and directs the laser beam.

- Optical System: Includes mirrors and lenses to focus and direct the laser beam.

- Work Table and Platform: A stationary or interchangeable surface where the material for cutting is placed.

- Gas System: Designed to supply auxiliary gas through a nozzle.

- Cooling System: A chiller is used to maintain an optimal temperature during the heat generation process.

- Filter System: Needed to remove dust and gas.

Modern CNC laser cutting equipment is a complex mechanism that combines mechanical, optical, electronic components, and software. The correct operation of each component affects the machine’s efficiency, productivity, and cut quality.

Types of Laser Cutting Machines

The key element of laser cutting machines is the laser source, which generates and directs a powerful light beam onto the material. This source determines the characteristics and application of the equipment.

Based on the type of laser source, there are different types of machines:

1. Fiber Laser Cutting Machines

This is a versatile and the most popular type of equipment for laser cutting. It has a high speed, is energy-efficient, and compact. It is suitable for processing various metals, including steel, gold, aluminum, and copper.

This type of machine uses optical fibers with doping elements, which helps to amplify the laser radiation with minimal energy loss.

Advantages of fiber machines:

- High productivity and efficiency.

- Reduced energy consumption.

- Durability of the laser source.

- Excellent cut quality.

The laser has a wavelength of about 1.064 µm. It can achieve a small focus diameter, which provides a more precise and clean cut.

2. CO₂ Laser Machines

These machines use a laser for cutting plywood, wood, plastic, and other materials. It is used less frequently for metal, as it requires high power for processing. However, it is suitable for cutting thin metal sheets.

Advantages of these machines:

- Low equipment cost.

- Fast cutting speed.

- High quality of engraving.

- Versatility.

The laser beam is generated using a gas mixture of carbon dioxide, helium, and nitrogen. It has a wavelength of 10.6 µm. It is suitable for both cutting and engraving.

3. Solid-State Laser Machines

The operating principle of these machines is based on YAG and YVO crystals doped with rare-earth elements. This type of laser is suitable for cutting thin metal and alloys. The machine is used not only for cutting but also for welding and marking.

Advantages of this machine:

- High power and precision.

- Ability for micromachining.

- Compactness.

- Fast cutting of hard materials.

These machines are less popular because they are expensive, but due to their high efficiency, they consume less electricity, which allows for a reduction in operating costs.

The choice of machine should be based on the materials to be processed and the productivity requirements. If you need laser cutting of aluminum and other non-ferrous metals, a fiber machine will be the best option. If you need to cut various materials, including metals, wood, leather, and plastic, a CO₂ laser machine is suitable. For micromachining and marking, a solid-state machine can be installed.

Types of Metal Laser Cutting Machines

There are different types of laser machines. All models differ in laser type, design, purpose, and technical characteristics. To choose the optimal option, you need to consider the type and thickness of the material, production tasks, cutting speed requirements, and your budget.

By design, the following types of machines are distinguished:

- Sheet metal cutting machines: This is the most common option, suitable for solving most tasks. This equipment performs laser cutting of metal sheets of different thicknesses. They can be open-type with a single table or closed-type with interchangeable tables.

For example, the LD-E series presents closed-design models that are highly reliable and efficient, with an intelligent cutting system. The LD-S series includes open-type models that ensure precise alignment, smooth operation, and high productivity, suitable for various metals.

- Tube cutting machines: Designed for cutting all types of tubes and shapes (round, square, etc.), as well as rolled products. The LD-T series models are equipped with a laser head rotation function and a pneumatic chuck for stable material feeding. This equipment is adapted for cylindrical and profile workpieces. Laser cutting of pipes provides a narrow kerf, which reduces material waste and results in smooth edges.

- Combined machines: These are multifunctional machines that combine the capabilities of cutting both metal sheets and pipes. Their advantages are versatility, space savings, and cost efficiency when you need to cut different types of products. The LD-Q series models are distinguished by double efficiency and continuous material feeding. The size of the pipes suitable for processing ranges from 20-220 mm.

- H-beam steel profile laser cutting machine: Designed to work with larger and heavier materials than sheets or pipes. The laser beam is used for cutting profiles and I-beams, piercing holes, and forming complex contours. The LD-H series models are equipped with a convenient frame for transporting items, a helical rack that ensures smoother and quieter movement, and a reliable gearbox resistant to shocks and vibrations. Thanks to their design, these machines can cut material at different angles, which improves the quality of metal structures.

In addition, LD Laser offers a metal laser cutting machine at an angle of 0-45°. Thanks to a special cutting head that can tilt at a specified angle, various angled cuts can be made in one pass. The cutting precision and smooth edges eliminate the need for subsequent material processing. The parts are immediately ready for welding, which speeds up the production process.

Each type of equipment is a solution optimized for a specific material. The variety of laser machines makes it easy to solve even the most complex tasks in the field of metal processing. By choosing the right model depending on the specifics of production, enterprises can increase productivity, reduce costs, and ensure high product quality.

Buy a High-Quality Metal Laser Cutting Machine in Ukraine from LD Laser

LD Laser is a reliable supplier of CNC machines that can solve various tasks in many industries. All equipment is distinguished by efficiency and high-quality cutting, and is suitable for various materials.

The manufacturer LD Laser offers powerful laser machines with rigid welded frames without power beams under the working area, so the structure is not subjected to heat during operation. Thanks to the high travel speed, the equipment processes the material quickly without losing quality. This means it allows for accelerating the production process and getting a smooth cut on any products.

7 Reasons to Buy LD Laser Machines:

- Certified equipment that meets European quality standards (CE and ROHS certification).

- Reliability and safety of the machines—they undergo multi-stage quality control, including a check of the equipment’s correct operation before delivery.

- Material versatility—laser cutting of stainless steel, aluminum, copper, and other metals in the form of pipes, sheets, profiles, and workpieces is possible.

- Wide model range—machines for different tasks.

- Automation of the cutting process thanks to the CNC system.

- Operator protection—closed protective casings to protect workers from sparks, laser radiation, and smoke.

- Ease of setup and control.

The price of a laser metal cutting machine, which depends on the design, technical capabilities, and purpose, allows for the creation of parts of any complexity, such as sharp corners, thin lines, and small-diameter holes, thanks to its precise cut.

The availability of our own warehouse and service centers simplifies the delivery and maintenance of the equipment.

Our company is the official representative of the LD Laser manufacturer in Ukraine. We offer a wide range of services—from selecting the optimal model to after-sales service. Fast delivery and installation of the machines allow for production to be started without delays, and thanks to technical support, any malfunction or failure can be quickly eliminated, minimizing downtime.

LD Laser’s technical solutions are the choice of enterprises that want to get reliable, safe, and high-tech equipment that ensures cutting accuracy. You can buy a laser metal cutting machine to solve many tasks in different industries.

Application of Metal Laser Cutting Machines

Laser cutting machines are versatile. Thanks to their high precision and speed, they are suitable for use in various industries, design, and advertising.

Where is a laser cutting machine used?

- Mechanical engineering and the automotive industry: Cutting body parts, frames, suspension components, processing complex shapes made of sheet metal, and creating prototypes.

- Aerospace and shipbuilding: Manufacturing components from durable alloys for cladding, engines, turbines, and internal structures.

- Electronics: Creating metal casings for PCs, circuit boards, servers, and other electronic devices.

- Construction and architecture: Cutting metal beams, pipes, and profiles needed to create frameworks and load-bearing structures, and manufacturing panels, fences, decorative, and connecting elements.

- Metalworking: Manufacturing parts for equipment.

- Household appliance production: Cutting components for refrigerators, washing machines, and other appliances, and manufacturing metal frames.

- Design and advertising: Creating metal signs, billboards, artistic compositions for decoration, etc.

The wide application of these machines is due to the fact that a laser for metal cutting provides a high-precision cut and a clean edge on different types of metal, which does not require subsequent processing.

Software for Metal Laser Cutting Machines

Software affects cutting accuracy, process automation, the implementation of non-standard ideas, and equipment efficiency. Software covers the preparation of sketches, manufacturing, and management of the cutting process. Various programs are used for this:

- Design software: CAD (Computer-Aided Design) is used to create cutting drawings. The most popular tools are AutoCAD, Fusion 360, etc. The choice of program depends on the task, complexity, and specific features of the project.

- CAM (Computer-Aided Manufacturing): Converts CAD drawings into a special code (most often G-code) that controls the laser beam. This software is necessary for production preparation. It ensures accuracy by correctly calculating the path and setting the necessary cutting parameters.

- Machine control software: CypCut is one of the popular control systems. It is responsible for interpreting G-codes, regulating speed, and controlling the movement of the laser head. Thanks to the software, the machine for laser cutting of stainless steel, aluminum, and other metals performs the assigned tasks.

- Nesting software: Used to optimally arrange items on a metal sheet and minimize waste. This is especially important when working with expensive materials.

The efficiency of the equipment depends on the software. With its help, you can adjust cutting parameters, direct the laser beam, control the gas supply, and monitor the technical condition of the machine.

The choice of software depends on the type and model of the machine, the scale of production, and other factors.

What Materials Can Be Processed on LD LASER Machines?

LD LASER manufactures different types of machines to solve various production tasks. All products differ in design and type of laser source, which allows you to choose the optimal option for the required material. If you need effective laser cutting, the metal must match the characteristics of the specific machine. In general, the equipment is suitable for processing metal sheets, pipes, profiles, and rolled products.

What materials can be worked with:

- Carbon and stainless steels.

- Aluminum and its alloys.

- Copper.

- Other non-ferrous metals.

- Bronze.

- Brass.

- Pipes of different cross-sections.

- H-beams, etc.

For more detailed information on the technical capabilities of laser cutting machines, the materials suitable for processing, and the features of LD LASER equipment, please contact our managers. For a consultation, call us, send a request to a convenient messenger, or fill out the contact form on our website.

Laser machines for cutting metal can significantly improve the quality of finished products, increase production speed and productivity, optimize work processes, and reduce material consumption. Buying a metal laser cutting machine means expanding production capabilities and gaining a competitive advantage. This is a strategic step for any enterprise that intends to quickly adapt to market changes and produce high-quality products that meet standards.

If you want to take your production to a new level and ensure maximum productivity without unnecessary material waste, submit an application for a laser machine at LD LASER. We offer favorable terms of cooperation and affordable prices.

Frequently Asked Questions

How much does a laser metal cutting machine from LD Laser cost?

LD Laser offers a variety of metal laser cutting machines. The price will depend on the specific model, its technical capabilities, and its intended purpose. You can get a price estimate for our machines by contacting our managers by phone, or you can send a request for a quote via messenger or email. After processing your request, we will contact you to discuss all the details and calculate the cost of the machine based on your requirements.

Who needs metal laser cutting?

Laser cutting (for aluminum, copper, brass, stainless steel, other metals, and alloys) is used by businesses that want to ensure high cutting precision, increase task completion speed, and improve the quality of their finished products. Specifically, laser machines are essential for companies in mechanical engineering, the automotive industry, metalworking, aerospace and shipbuilding, medical equipment, and the production of household appliances and electronics, among others.

This makes laser cutting a key technology for manufacturing high-quality parts, components, and artistic structures of any complexity and shape.

What is CNC laser cutting?

If you need precise metal laser cutting, a CNC machine is the best solution. This is a modern, high-tech piece of equipment that automates the process of cutting sheet metal and ensures a clean cut for pipes or profiles according to specified parameters.

CNC stands for Computer Numerical Control. It is a system that manages the machine’s functions—namely, directing the laser beam, controlling the speed, and the depth of processing. A computer reads the instructions and moves the laser along the required path. This allows for the rapid production of any item with smooth and clean edges, which is difficult to achieve with manual work.

This technology helps to speed up the production process, minimize waste, and reduce the risk of workplace injuries.

What is laser cutting used for?

A metal laser cutting machine is used for the high-precision and fast processing of various products. Its tasks include:

- Cutting sheet metal.

- Cutting complex-shaped parts from various materials.

- Manufacturing structures and components.

- Creating decorative metal elements.

- Prototyping.

Laser cutting is suitable for mass production of parts as well as for fulfilling individual custom orders.

What are the advantages of laser cutting over traditional mechanical methods?

Laser cutting is a modern technology that delivers better results compared to traditional processing methods.

Advantages of laser cutting:

- Non-contact production process.

- High cutting precision.

- High processing speed.

- Elimination of material deformation and tool wear.

- Reduced waste.

- Versatility.

Laser cutting is suitable for solving most production tasks and is used for processing a variety of materials, including metal, plastic, leather, wood, and others.

How does laser cutting work?

A laser cutting machine uses a focused, high-power light beam. This beam heats, melts, and vaporizes the material, leaving a clean and smooth cut.

The process involves a laser beam for cutting and a special gas to remove the residue of the molten material. The entire process is controlled by a computer program. Thanks to this, the laser cutting of steel, aluminum, stainless steel, and other metals helps to increase production efficiency.

Can aluminum be cut with a laser?

Yes. However, it requires the right kind of laser metal cutting. Fiber optic machines, which are characterized by high power, are the best choice for this.

Since aluminum has high reflectivity and dissipates heat quickly, a powerful laser is needed to melt the material fast enough so that it doesn’t cool down while the light beam moves.

LD LASER’s laser machines are suitable for cutting and processing aluminum. For a consultation and assistance in choosing the optimal machine, please contact our managers by phone, messenger, or through the form on our website.

Where is laser cutting used?

Laser cutting of stainless steel, carbon steel, copper, brass, and other metals and alloys is used in many industries, in the production of household appliances and electronics, in furniture manufacturing, and in advertising and design.

Where can I buy a laser cutting machine in Dnipro?

LD LASER in Dnipro is the official representative of a manufacturer of high-tech CNC machines for laser cutting and metal processing.

We offer reliable and safe laser metal cutting machines of various types that can handle both simple and complex tasks. They can produce items of any shape with clean and smooth edges that do not require additional processing. To get help in choosing the right equipment for your tasks and to place an order, call us, send a message via WhatsApp, Viber, or Telegram, send an email, or fill out the form on our website, and we will call you back.