Laser Cutting of Tubes and Rolled Metal Products (Profiles)

In manufacturing and industry, high precision and productivity are of great importance. Therefore, enterprises use modern technologies, among which laser cutting of tubes and rolled metal products occupies a special place. This method allows for increased production efficiency, reduced manufacturing costs, and ensures high quality of finished products. Thanks to its high accuracy, repeatability, flexibility, and cut cleanliness, the technology is indispensable in those industries where impeccable geometry of products is required and where it is necessary to create complex parts of non-standard shapes.

What is Laser Cutting of Tubes and Profiles

Laser cutting of tubes and profiles is a high-precision and fast method for processing metal blanks, where the material is cut using a powerful, focused laser beam. This is a popular technology that expands production capabilities and is in demand for manufacturing products with a complex contour. It is suitable for creating products of any complexity without compromising quality.

For cutting tubes and profiles, CNC (Computer Numerical Control) equipment is used, equipped with rotating systems for feeding blanks and securely fixing them.

A machine for cutting tubes and rolled products allows for the implementation of any engineering solution due to its maximum precision, speed, and a smooth, clean cut. It can cut items of various shapes, thicknesses, and sizes.

Technology of Laser Cutting of Tubes and Rolled Metal Products

Laser cutting of tubes and rolled metal products is an important production stage, as it ensures the creation of products with the desired shape and a clean edge that does not require additional processing. This contributes to the optimization of production processes, reduction of costs, and acceleration of product manufacturing.

Special equipment is used for cutting sheet metal, tubes, and profiles, the operation of which is based on the impact of a laser on the material. The essence of the technology is that a light beam is directed at the blank, which locally heats the metal to its melting temperature. As a result, the material melts along a clearly defined line, which forms a smooth and clean edge.

The laser machine is controlled by a CNC system, which allows for the automation of work processes, achieving maximum precision in cutting, and high repeatability.

Stages of Laser Cutting of Tubes and Rolled Metal Products:

- Preparation of the Layout. A file is developed that specifies all the main cutting parameters.

- Equipment Setup. The program is loaded, and the speed, cutting depth, and other important parameters are configured to ensure high-quality products.

- Focusing of the Laser Beam. First, the light beam is generated, then this stream is converted into a narrow point through the optical system and directed onto the surface of the material.

- Cutting Process. The laser beam moves along a predetermined trajectory, quickly cutting the blank and forming an even and smooth cut. Simultaneously, an assist gas, most often nitrogen or oxygen, is fed into the cutting zone, which blows away the molten metal.

To achieve high accuracy, the laser cutting machine for tubes and profiles provides for the rotation of the blank or the laser head. In addition, such equipment is equipped with special systems for convenient feeding and secure fixation of the material.

Laser cutting technology ensures a clean cut, allows for the creation of holes and slots, and the manufacture of products with complex geometry and according to individual designs. Therefore, laser processing has wide application in various industries and is indispensable both in the mass production of parts, where accuracy and repeatability are important, and for the manufacture of non-standard products when complex tasks need to be solved.

Undeniable Advantages of Laser Cutting of Tubes and Profiles

Thanks to its versatility, high precision, and speed, laser cutting increases productivity, provides flexibility in creating complex contours, and allows for improved quality of finished products. Laser equipment for cutting rolled metal and tubes is easily integrated into production lines and increases production efficiency through process automation and minimizing errors due to human factors.

Why laser cutting is a profitable solution:

- Maximum precision and repeatability – thanks to the minimum kerf width and programmed control, an even clean cut is achieved, with full compliance with the product’s size and shape, which allows for the manufacture of identical parts in large quantities;

- Ideal cut – laser cutting ensures an even and smooth edge without burrs or jagged edges, which does not require subsequent grinding;

- Absence of material deformation – localized heating of the metal occurs only in the cutting zone, so other areas of the material remain undamaged;

- High speed – the CNC system accelerates and simplifies the cutting process, thereby increasing productivity;

- Minimal waste – a narrow, high-precision cut allows for rational use of the material;

- Process safety – thanks to programmed control and the absence of direct contact during cutting, the likelihood of errors and damage is reduced;

- Implementation of complex projects – laser cutting is suitable for manufacturing products of non-standard shapes, with complex contours, and small elements;

- Versatility – used for cutting tubes and profiles of all shapes, made from a wide variety of metals.

Thus, the fiber laser for profiles and tubes is a profitable investment in manufacturing. After all, the equipment allows not only for improving production indicators but also for gaining a competitive advantage due to the rapid manufacture of high-quality products, regardless of the level of complexity and detail.

What Materials and Shapes Can Be Processed on Equipment for Cutting Tubes and Rolled Metal Products

Modern laser machines designed for cutting tubes and rolled metal products are suitable for working with various materials and products of different shapes. In particular, most metals can be processed with a laser.

Types of Materials for Cutting:

- ferrous metals – carbon and low-alloy steel;

- stainless steel;

- aluminum and alloys;

- non-ferrous metals – copper and brass.

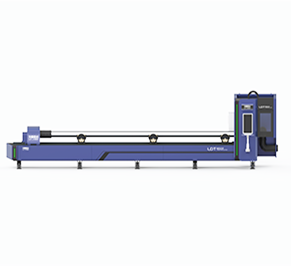

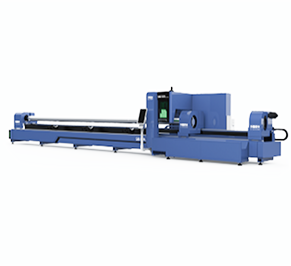

The LD Laser fiber machine for laser cutting of tubes and profiles is versatile, powerful equipment that is distinguished by its precision and flexibility in processing blanks. These machines can cut:

- tubes – round, oval, square, rectangular shapes;

- rolled products – angles, I-beams, channels, profiles, and strips;

- special profiles and non-standard blanks – according to individual order.

In addition, laser machines are used not only for cutting sheets and profiles and tubes of different shapes but also for piercing holes, creating slots, and chamfering.

Application of Laser Cutting of Tubes and Profiles

Laser cutting allows for reducing the production cycle, decreasing waste and defects, achieving high product repeatability and an ideal cut, which makes it relevant in many industries – from mechanical engineering and construction to design and advertising. Thanks to the technology, serial production of parts can be launched, as well as the manufacture of non-standard products with complex geometry.

Laser equipment for cutting rolled metal and tubes is in demand in the following areas:

- Aerospace, mechanical engineering, and automotive industry – manufacturing of frames, bodies, supports, chassis, mounting units, mechanism elements, chassis components, handrails, seat profiles, etc.;

- Construction – production of frameworks, stair and other structures, canopies, railings, fences, beams, frames, etc.;

- Architecture and design – creation of decorative structures, including those with artistic patterns, facades, panels, billboards, interior elements;

- Oil and gas industry and energy – manufacturing of components for collectors, pipelines, reservoirs;

- Medicine – manufacturing of equipment elements, stands, stretchers, trolleys, etc.;

- Furniture production and commercial equipment – production of frameworks, display cases, shelving, etc.

Since the laser beam ensures a smooth cutting line and a clean cut without material deformation, there is no need for further processing of the products. This simplifies and accelerates production, which is beneficial for enterprises in various industries.

How to Choose a Laser Cutting Machine for Tubes and Rolled Metal Products

To choose the optimal equipment for cutting round rolled metal, tubes, and profiles, it is necessary to proceed from the specific requirements and tasks of production. Each model has certain technical parameters, so it is suitable for processing different blanks.

When choosing, you should focus on the following key parameters:

- type and power of the laser – the more powerful the source, the greater the thickness and speed of the cut;

- wall thickness of the tube or profile;

- processing zone – for understanding the possible dimensions of the blanks;

- maximum diameter or cross-section of the profile;

- movement speed;

- positioning accuracy – this affects the quality of the cut.

For processing thick-walled tubes or large-diameter profiles, it is better to purchase a high-power machine. And if it is necessary to cut products with a complex contour or manufacture large batches, equipment with automatic feeding and a clamping system should be installed for secure fixation of the blanks.

LD LASER company in Dnipro offers high-precision machines for laser cutting of tubes and profiles of different types, shapes, and sizes. All models comply with European quality and safety standards and have passed CE and ROHS certification. The equipment is equipped with a CNC system, which simplifies control and allows for process optimization. It ensures fast and accurate cutting, high repeatability, and clean edges without burrs and material deformation. It is distinguished by high power and energy efficiency.

We provide the full range of services – from assistance in selecting the optimal machine to its setup and technical maintenance. Thanks to our own service center, the professionalism and long-term experience of our specialists, we help solve tasks of varying complexity and implement any projects.

If you do not know which laser cutting machine to choose for your production, contact us by phone, via messenger (WhatsApp, Viber, or Telegram of your choice), or through the form on the website, and receive professional consultation. We will help you select equipment that meets your requirements and advise you on all issues related to the installation, operation, diagnostics, and technical maintenance of CNC laser machines.

Order an LD LASER rolled metal or tube laser cutting machine and ensure precise, fast, and safe metal processing, regardless of the scale of production.

How can we be of use to you?

Frequently Asked Questions

The cost of equipment for laser cutting of rolled metal and tubes depends on the laser power, the machine design, the size of the processing area, and additional functions. Models with higher power, which ensure greater cutting speed with minimal errors and are equipped with systems for stable feeding of blanks into the cutting zone, will cost more.

When choosing equipment, it is necessary to compare the production tasks with the technical characteristics and capabilities of different models. You can familiarize yourself with the parameters of the machines on our website, and to find out more about the features of their operation, call us by phone.

LD LASER laser cutting machines are controlled using a CNC system. This is modern, high-power equipment that is suitable for solving various production tasks. It ensures maximum accuracy, fast processing, and a cut without jagged edges.

If you are interested in the price of a laser cutting machine for profiles and tubes, contact our managers using a method convenient for you or leave a request on the website.

On a laser machine, you can cut tubes and profiles of various shapes and sizes. Such equipment is indispensable in production where accuracy, repeatability, and speed are important, a clean cut is required, and the manufacturing of products with complex configurations, including custom designs, is performed.

Equipment for cutting round rolled metal, square and rectangular tubes, various profiles, and reinforcement allows for the fast production of large volumes without loss of quality.

Functions and capabilities of a rolled metal cutting machine:

- cutting tubes, beams, and profiles;

- creating holes, slots, and chamfers;

- cutting parts with a complex contour;

- straight and figured cuts.

LD LASER machines process blanks made of steel, stainless steel, aluminum, copper, brass, and various alloys. They are suitable for the manufacture of structures, furniture and equipment elements, fences, facades, components of mechanisms and assemblies, casings, pipelines, and much more. They are used for serial production and the implementation of complex, non-standard engineering solutions.

If laser equipment is used for cutting rolled metal and tubes, a wide range of metal blanks can be processed. The main limitation here is related not to the type of profile and shapes, but to the length, diameter, and wall thickness of the tube.

Suitable for cutting on the machines:

- round, oval, square, and rectangular tubes;

- profiles of complex cross-sections (H, T, L-shaped, etc.) – channels, I-beams, angles, etc.;

- decorative profiles – non-standard products that are needed for the implementation of architectural and design projects.

If you are in doubt about which rolled metal cutting machine to choose, call us and get a consultation. Our specialists will help you select the optimal equipment taking into account your requirements, which will be a successful option for solving specific production tasks.

All laser machines that are used for cutting tubes and rolled metal products differ in design, laser type, and characteristics.

For example, the design and features of the processing zone affect the technical capabilities of the machine, that is, its purpose. Accordingly, models are distinguished for cutting sheet metal and tubes, angular cutting, I-beam cutting, and combined machines for cutting tubes and rolled metal, including profiles and sheets.

By laser type, machines are:

- fiber – this is powerful and energy-efficient equipment that is suitable for cutting different metals and blanks of any shape;

- CO₂-lasers – these are gas lasers that are suitable for processing thin metal, but are more effective when cutting non-metals.

The optimal solution for enterprises in various industries is the fiber laser for profiles and tubes. This is universal, safe equipment, the advantages of which are high accuracy, power, and cutting speed, which allows for increased productivity, reduced waste, minimized defects, and lower operating costs.

At LD Laser company, you can buy a laser cutting machine for the material you need. You can familiarize yourself with the assortment and parameters of different models on the website, and to receive a consultation, clarify prices, and place an order, contact us by phone, in the messengers WhatsApp, Viber, or Telegram, or leave a request online, and we will call you back.

Laser and plasma cutting are different material processing technologies. Their differences lie in the operating principle, speed, accuracy, cut quality, and technical capabilities.

A laser cutting machine for tubes and rolled metal products generates a narrow powerful laser beam that focuses on the material, while plasma cutting uses ionized gas. In both the first and second cases, the metal melts and is blown out of the cutting zone. At the same time, with laser exposure, the positioning accuracy is $\pm 0.05$ mm, and with plasma cutting, it is $\pm 0.3-0.5$ mm.

The laser provides a narrow cut, which allows for obtaining a smooth and clean edge without burrs, while with plasma cutting, the edge can be uneven and melted.

On a laser machine, the most diverse metal blanks can be processed, but with restrictions on the wall thickness – up to 10 mm. Plasma cutting, on the other hand, is capable of handling thicker materials.

Thus, a plasma machine will be a good solution for cutting metals thicker than 25 mm, and laser equipment is indispensable where maximum accuracy, repeatability, and an ideal cut are required when working with tubes and profiles having a wall thickness of up to 10 mm.

To learn more about the possibilities of laser cutting, contact our specialists by phone for a consultation.

You can buy a high-precision and powerful laser cutting machine for tubes and profiles at competitive prices and without intermediaries at LD LASER company in Dnipro. This is the official representative of the Chinese factory-manufacturer of laser metal processing machines in Ukraine. The equipment is manufactured in accordance with European quality standards, which is confirmed by CE and ROHS certificates. The machines are reliable and safe, have a long service life provided they are used correctly, and help in solving complex tasks.

In our company, you can not only buy a high-precision modern rolled metal cutting machine but also receive assistance in choosing the optimal model for the requirements of a specific production and ensure the uninterrupted operation of the equipment through quality technical support.

Technical maintenance, which our specialists conduct, allows for keeping the machines in working condition, ensuring process safety, and avoiding long downtimes due to unexpected breakdowns. We will set up the equipment, perform diagnostics, update the software, and replace worn or damaged parts.

LD LASER equipment for cutting tubes and rolled metal products is suitable for processing blanks and products of standard and non-standard shapes, working with parts with complex geometry, and serial and custom production.

Buy a rolled metal or tube laser cutting machine to increase work efficiency, shorten the production cycle, and produce products that meet high-quality standards. To place an order, fill out the form on the website, send a request in WhatsApp, Viber, or Telegram, or contact the managers by phone.