Laser Cutting Machine for Sheet Metal

Modernization of production leads to increased productivity, reduced operating costs, and improved quality of finished products. Therefore, enterprises in various industries working with metal that want to scale and gain a competitive advantage use CNC machines. Thanks to such equipment, laser cutting of sheet metal guarantees accurate geometry, an even cut, and a smooth, clean edge that does not require subsequent mechanical processing. This, in turn, allows for the manufacture of parts and structures of any complexity and configuration, regardless of the level of detail. Moreover, laser metal cutting machines are suitable for both mass production and the manufacturing of custom-made products.

Why a Laser Cutting Machine for Sheets is Needed

Due to its strength and versatility, sheet metal is in demand in various fields—from industry to construction and design. It is used for manufacturing small items, minor components, and large-sized structures.

For the production of high-quality products, reduction of waste, and defects, it is important to obtain an even and smooth cut without material deformation when nesting sheet metal. This is achieved by a sheet cutting laser machine, which ensures high precision and speed with attention to detail in its work.

Advantages of CNC laser machines for metal cutting:

- High cutting speed – thanks to the laser and a special control system, the machine quickly cuts metal, which is especially beneficial for the production of large batches of goods;

- High precision – the laser cuts any, even the smallest elements, with minimal tolerances up to 0.1 mm;

- Even edge – the cut is neat and smooth, without inaccuracies, so additional processing is not needed;

- Reduced waste – the software (SW) ensures optimal placement of all elements on the metal sheet;

- Versatility – machines are suitable for working with various metals, including steel, aluminum, copper, and alloys of different thicknesses;

- Complex geometry – the laser is suitable for creating holes, recesses, and complex contours;

- High repeatability – thanks to the laser, any lines can be replicated, consistently reproducing identical parts of the same size and shape in any quantity;

- Absence of metal deformation – a thin laser beam affects only the cutting zone, leaving surrounding areas untouched.

An open-type or closed-type laser machine allows for the automation of work processes, increased productivity, minimization of manual labor, and reduced human error influence. Therefore, enterprises can avoid mistakes, reduce the amount of defects, and speed up production without losing the quality of the manufactured products.

Laser Sheet Metal Cutting Technology

Laser cutting is a modern, universal technology for processing various metals on a high-precision CNC machine. Its essence lies in using a focused laser beam for the precise nesting of sheet metal of various thicknesses. Thanks to the SW and a special control program, the laser is directed along a specified trajectory, creating a clear cut.

The technology ensures not only high precision and speed of production but also flexibility in the process of manufacturing products.

Laser sheet cutting is fully automated. The developed program sets the trajectory of the laser beam, determines the cutting speed and depth, and then the machine performs the necessary tasks. Furthermore, the equipment can be easily readjusted, so the operator can effortlessly control the process and even switch from one material to another—in accordance with production requirements.

Stages of sheet metal cutting:

- Development of the control program. A digital model of the part is created, and the cutting program is loaded, which determines the trajectory of the laser beam.

- Equipment setup. Cutting parameters are adjusted, and the laser beam is focused.

- Metal cutting. The light beam locally heats the material to the melting temperature, and a special gas blows the molten metal out of the processing zone and ensures cooling of the areas.

After laser cutting, the blanks are removed from the sheet. The products have even edges, so they do not require additional grinding and can be passed on to the next production stage.

Thanks to non-contact action, material deformation is excluded, and automated control ensures maximum precision with minimal cut width.

Principle of Operation of a Laser Machine

The equipment used for laser cutting of sheet steel, aluminum, and other metals includes a working table where the material is placed, a laser source, a laser head, a cooling unit, CNC, etc. Thanks to this design, the machines are suitable for processing sheet material of various sizes.

The operation of laser equipment is based on the action of a laser beam, which is generated using a specific laser source. Concentrated light energy is directed onto the material along the trajectory specified by the program.

How the laser beam affects sheet metal:

- A powerful light beam is focused on a very narrow point on the metal surface;

- Local heating of the material occurs in a specific zone;

- The metal melts at the point of impact;

- The molten material is removed using a gas jet, such as oxygen and nitrogen.

The CNC ensures the movement of the laser beam along the specified line. Correct machine setup ensures cutting accuracy, clean cuts, and the absence of overheating and deformation of products.

Since cutting is performed using a light beam, the metal is not subjected to mechanical stress, which excludes damage and reduces equipment wear.

A modern laser machine for sheet cutting is used for working with stainless steel, brass, aluminum, copper, and other non-ferrous metals, as well as various alloys. It allows for solving various production tasks, including fine processing and the creation of complex contours.

The Secret of an Ideal Cut

The quality of the cut affects not only the finished product but also productivity in general. With a smooth surface of the products and the absence of burrs and material deformation, there is no need for subsequent grinding or other processing. This saves time in the process of manufacturing parts, reduces production costs, and increases production efficiency.

What affects the quality of the cut:

- Focusing – a focused beam allows cutting to the required depth, which ensures a clear cutting line;

- Laser power – a powerful light beam is capable of cutting even thick sheets, leaving a clean cut;

- Cutting speed – to obtain an even cut, the parameters are adjusted depending on the type and thickness of the metal;

- Automation and control system – the program ensures not only more accurate cutting but also repeatability.

A CNC machine for sheet cutting, when all parameters are correctly set, allows for achieving high cut quality. The edges of the products will be even, smooth, without drips, roughness, or jagged edges, and the parts will maximally match the specified dimensions. In addition, no melted particles remain on the surface due to the fact that the laser quickly heats the material exclusively in the cutting zone, so other areas do not melt, and pieces of metal do not stick to the edges.

What Can Be Done with Sheet Metal on a Laser Machine

Laser cutting technology allows for solving many production tasks. The main function of the laser is nesting, cutting, and processing metal.

Equipment for processing sheet metal has the following capabilities:

- Processing soft and hard metals;

- Cutting small and complex elements, parts of non-standard shape;

- Creation of curved cutting lines;

- Nesting of thin metal sheets;

- Cutting various types of metal, including steel, aluminum, titanium, etc.;

- Creation of grooves and holes of various diameters;

- Prototyping and manufacturing of parts.

Thanks to laser cutting, it is possible to manufacture parts, components, various structures, showcases, panels, mounting plates, signs, billboards, grilles, souvenirs, enclosures, fencing systems, decorative elements, and others. The technology is widely used in various fields, including mechanical engineering, electronics, automotive and other industries, various manufacturing sectors, advertising, and design.

Types of Machines for Sheet Metal

Metal cutting equipment differs depending on the type of laser source. Each type of equipment has its own characteristics and is designed to solve specific problems.

Popular machines for sheet cutting in Ukraine:

- Fiber laser machines. They are considered the most demanded due to their high efficiency and versatility. The principle of operation of the equipment consists of directing a beam from diodes into optical fiber, doped with rare-earth elements, where a powerful laser beam is generated. It is transmitted to the metal surface via an optical fiber cable. Its wavelength is approximately 1.06 µm. The machines are suitable for cutting various materials, ensuring high cutting speed, maximum precision, a narrow kerf, and a smooth edge.

- CO2 lasers. These are gas lasers involving the generation of a light beam in a sealed tube and the use of mirrors for its delivery and focusing. Suitable for processing non-metals and some types of metal, such as stainless and carbon steel.

If high-quality laser cutting of sheet metal is needed, fiber-optic machines will be the optimal choice due to their high speed, energy efficiency, versatility, reliable design, and low operating costs. This equipment is used for most tasks in metal processing.

Open- and Closed-Type Laser Machines: What is the Difference

The main difference between open- and closed-type laser equipment lies in the design and, consequently, the degree of operator protection.

A laser machine with an open frame is equipment without a protective casing around the working area. This design provides excellent visibility, free placement and movement of metal sheets, which simplifies maintenance and speeds up production processes. It is suitable for manufacturing large-sized blanks, but at the same time requires increased safety measures, particularly concerning protecting workers from laser radiation.

Features of open-type machines:

- Open working area;

- Ease of loading and unloading material;

- Work with large-sized sheets;

- Convenience of maintenance;

- Good visibility and production control.

Such equipment should be installed in rooms with a good ventilation system. Moreover, for safe operation and high productivity, it is important that the machine is controlled by an experienced operator.

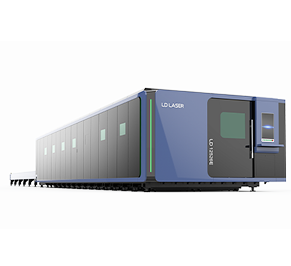

A closed-type laser machine is equipment with a closed working area. It ensures maximum personnel safety during the production process. Such machines reduce the noise level and protect the operator from laser exposure and smoke.

Features of closed-type machines:

- Isolation of the working area due to the presence of a protective casing or body;

- Cleanliness of the workplace due to the extraction and filtration system;

- Reduced cutting noise;

- Safety during the production process;

- Exchange table for speeding up machine loading and unloading;

- Viewing through windows.

Each model has its own features and advantages. Equipment must be selected based on the specifics and tasks of production.

Which Laser Cutting Machine to Choose for Sheets – Open or Closed Type

The choice of a laser cutting machine for sheet material depends on specific production tasks, production volumes, and safety requirements. For this reason, there is no universal solution—each type of equipment is needed for specific conditions.

If it is necessary to ensure maximum personnel safety, produce serial products, and comply with environmental standards, it is better to choose a closed-type CNC laser machine. If it is a small production, floor space is important, or flexibility in work is required, it is better to install an open-type machine.

Closed-type laser equipment is the standard for many industrial enterprises, as it allows the production process to be made safer, ensures cleanliness in the room due to filtration and removal of harmful gases, laser radiation, and smoke. This is a profitable solution for large enterprises engaged in the mass production of items.

Open laser machines are a more economical and flexible solution compared to closed ones. They are optimal for small companies with low turnovers and in case of cutting large-sized sheets or manufacturing non-standard products when it is impossible to load the material into a closed-type machine.

When choosing a laser machine, one must consider the materials that will be processed, safety requirements, speed, and access to the working area. If you do not know which laser machine is better to buy—closed-type or open-type—for your production tasks, contact the specialists of LD LASER company. You will receive professional consultation from us and can learn about the technical characteristics, advantages, and operational features of different types of laser equipment designed for cutting sheet metal.

Cost of Open- and Closed-Type Laser Machines

The price of both open- and closed-type machines will differ depending on several factors. Among the main ones are:

- Power and type of laser – a more powerful laser beam can cut metal faster, including thick sheets, so the price of such equipment will be higher;

- Size of the working table;

- Type of design – closed machines usually cost more than open ones due to compliance with safety standards, the presence of a protective casing, extraction, and filtration system;

- Configuration – additional options make the machine more expensive;

- CNC – Computer Numerical Control allows for automating and optimizing production processes, achieving high precision and part repeatability, so such equipment costs more.

LD LASER company offers powerful laser machines for cutting metal sheets of various types. All equipment meets European quality and safety standards. If you are interested in the price of a closed-type or open-type laser machine, contact our managers by phone, in messengers, or through the form on the website to receive a cost calculation for the equipment based on your requirements and production tasks.

Advantages of LD LASER Sheet Metal Laser Cutting Machines

LD LASER is a Chinese manufacturer of CNC laser machines designed for metal cutting, which focuses on innovative technologies. Thanks to the presence of its own research centers and constant quality control, the factory produces powerful equipment that allows for increased productivity while reducing operating costs.

The manufacturer offers a wide model range. Machines of closed and open types with different capacities are available for sale, adapted to the requirements of various markets and intended for solving various production tasks.

Why you should buy an LD LASER sheet cutting machine:

- High precision and repeatability;

- Wide range of power capacities for different tasks;

- Functionality and versatility – suitable for processing tubes or sheet steel, aluminum, titanium, copper, other metals, and alloys;

- High productivity;

- Process automation;

- Energy efficiency – fiber laser machines consume less energy;

- Safety and reliability – protective casings and smoke removal systems in closed-type machines, cutting mode control systems, etc.

The presence of an even, clean cut allows for avoiding additional subsequent processing of blanks, and the optimal placement of parts on the metal sheet leads to a reduction in waste. All of this combined helps reduce production costs.

Our company in Dnipro is the official representative of the Chinese manufacturer of metal cutting laser machines LD LASER. We offer powerful, durable, and reliable equipment that has passed CE and ROHS certification. Every CNC machine for sheet cutting, regardless of its design, allows for automating processes, increasing productivity, and reducing the amount of scrap and waste. The equipment ensures maximum cutting precision with repetition of part dimensions and allows for the production of high-quality goods. We perform diagnostics, setup, and service maintenance of the machines.

In our company, you can buy open- and closed-type laser machines in accordance with your production tasks. The equipment is suitable for processing sheet metal of various thicknesses. It is used for cutting all types of metal in a wide variety of fields—from industry and construction to advertising and design. To get a consultation, calculate the cost of a laser machine, and place an order, contact the managers by phone, leave a request in WhatsApp, Viber, or Telegram, or fill out the contact form on the website.

A modern laser machine with a CNC system for cutting sheet metal is a reliable investment in the development of your business! After all, it is an opportunity to increase productivity, reduce operating costs, and improve the quality of the products being manufactured.

How can we be of use to you?

Frequently Asked Questions

If you are looking for a powerful fiber laser machine with a cabin or an open working area, choose LD LASER. Our company is the official representative of this manufacturer in Ukraine. We offer high-precision equipment for various production tasks, as well as service maintenance. We will provide a consultation and help you select a suitable model based on your requirements and budget.

LD-S and LD-E series sheet metal laser cutting machines ensure high precision, speed, and repeatability. The CNC system simplifies equipment control and helps avoid human error. To get a consultation and place an order, call us by phone, send a message via your preferred messenger, or fill out the form on our website.

To correctly select and purchase a sheet cutting machine, you must first consider the requirements and specifics of your production.

What characteristics should you pay attention to:

- Type of metal for cutting – the machine must quickly cut the material you need;

- Laser power – this determines the speed of cutting sheets of different thicknesses;

- Working area size – corresponding to the dimensions of the sheet material;

- Machine design – open platform or with a closed enclosure;

- Control – the CNC system and software (SW) simplify production processes;

- Safety – how important the presence of an extraction and filtration system is.

LD Laser cutting machines are universal, making them suitable for working with stainless and carbon steel, aluminum, copper, titanium, various alloys, and other materials. Sheets of different thicknesses can be cut with maximum precision. All models are equipped with a CNC system for easy control and automation of work processes.

If you are unsure which sheet metal processing equipment to purchase for your production, our specialists will assist you with this matter. For a consultation, contact us by phone or via messengers.

The thickness of sheet metal for cutting depends on the type and power of the laser. The more powerful the equipment, the thicker the metal that can be processed on it.

Modern machines are capable of cutting steel sheets up to 50 mm thick, aluminum up to 30 mm, and copper up to 20 mm without inaccuracies.

Since even the slightest vibration can lead to a deterioration in cut quality when dealing with thick metal, work should be performed on machines with a CNC system. Thanks to specialized software, the laser beam can be precisely focused, directed along a given trajectory, and the cutting depth controlled. Thus, an open or closed metal laser cutter ensures high cutting speed and allows for the manufacture of products with a smooth, even edge. To get more detailed information about the technical capabilities of the equipment, contact our company’s managers.

Machines that perform laser sheet cutting are complex devices that require regular technical maintenance to ensure precise and fast cutting with an edge free of burrs and jagged edges.

Which components most often require replacement:

- Protective glass;

- Nozzles;

- Filters;

- Optical elements – lenses and mirrors;

- Chiller, etc.

Regular technical maintenance of the equipment helps to avoid overheating, damage to optics and other important components, and thus more costly repairs due to breakdowns.

Our company offers service maintenance of laser equipment to extend its lifespan, maintain high productivity and cutting accuracy, and minimize production downtime. We perform diagnostics, check contacts, and replace worn components with new ones when necessary.

If you need to check the laser cutting machine for sheets to confirm its functionality and efficiency, and to timely replace worn components to prevent equipment failure, contact our specialists by phone, via messengers, or through the form on the site.

Electricity consumption depends on the type of machine design, laser power, cutting frequency, and production volumes. The laser source, CNC, cooling, extraction, and filtration systems consume the most energy.

On average, laser machines can consume 4-25 kW per hour.

LD Laser equipment is widely demanded due to its high productivity, versatility, and energy efficiency. To get information on the power and energy consumption of the machine you are interested in, contact the company’s managers using the method convenient for you. Our specialists will provide a consultation and tell you how much electricity is consumed by laser cutting of sheet steel, aluminum, or other metals on a specific machine.

LD Laser machines are reliable and safe, but caution is still important during operation.

Key safety measures:

- Use protective equipment to protect against laser radiation, sparks, and hot metal;

- Install ventilation systems;

- Remove flammable objects from the cutting zone;

- It is mandatory to have a fire extinguisher in the workshop;

- Do not smoke near the machine;

- Train personnel to operate CNC machines;

- Regularly check the tightness of gas lines, the operability of the cooling system, and the integrity of the protective glass.

Open-type machines require enhanced safety measures because they do not have a protective casing, and their working area is exposed. To increase safety, you can buy a closed-type laser machine. But regardless of the type of design, all laser equipment requires technical maintenance for condition monitoring.

At LD Laser company in Dnipro, you can purchase a laser machine and order equipment service maintenance. To do this, fill out the form on the website, contact us by phone, or leave a request in WhatsApp, Viber, or Telegram.